In this article we’ll review common ABS system problems. With anti-lock brake systems on the market for more than three decades, some of the older technology has become problematic.

With that said, even some of the newer anti-lock brake systems experience malfunctions. Not only will we cover troublesome components, but we’ll talk about the operation of the warning light and how drivers can often mistake normal operation as a perceived problem.

In the final thoughts section at the end, we’ll cover how other automotive safety features like automatic traction control and ride stabilization uses the ABS system to carry out their functions. Before we start to review common ABS system problems let’s talk about why car manufacturers developed this technology. In addition let’s talk about what it means when the warning light comes on and what we should do about it.

The Basics of ABS Systems

The purpose of an anti-lock brake system is to prevent the skidding situation when the driver mashes down on the brake pedal. If a tire locks up it loses the ability to properly control the vehicle. The ABS system quickly applies and releases the brake on any wheels that show a lockup situation.

This gives the driver more control of an automobile during a panic stop situation. In the old days they told us to pump the brake pedal on icy roads. Now the driver can just push as hard as they want on the brake pedal and the ABS system accomplishes the same task automatically.

One of the major sensors deployed on the automobile provides wheel speed information to the anti-lock brake computer. They often mount these wheel speed sensors on a backing plate. Although this plate provides some protection the sensor remains exposed to the harsh elements, road salt and flying debris. If the sensor becomes damaged the computer turns on the ABS warning light to notify the driver that the system isn’t functioning properly.

Whenever you see an ABS warning light this is an indication that a trouble code has set in the brake computer. These trouble codes can point you in the direction of the malfunction. This greatly reduces diagnostic time and removes the guesswork so you’re not replacing unneeded parts.

Diagnosing ABS Systems

Although the ABS diagnostic system stores trouble codes like the power-train control module, many differences exist between the two on board diagnostic systems. If you set a trouble code in the power train system you’ll need to clear this code after completing the repairs.

However, the antilock brake module constantly monitors the sensors and operation of the system. In other words, if a wheel speed sensor gets crushed by road debris the brake module sets a trouble code for this sensor. After you replace the damaged wheel speed sensor the car’s computer automatically sees the completed repairs after a short drive. The light goes out and it’s not necessary to clear any set trouble codes. Again that’s why they call it a constantly monitored system.

Expensive and Common ABS System Problems

Unfortunately, some models of automobiles became famous for expensive ABS system problems. Let me provide an example of cheap versus expensive. If a wheel speed sensor fails, parts and labor to replace this item run around hundred dollars on many cars. However, some aging ABS systems are known for modulator valve problems. This part of the system controls and allows hydraulic fluid to flow to individual calipers.

In other words, this is how the system physically pulses the brakes to stop efficiently. Many manufacturers built these modulator valves into an assembly that contains the EBCM (electronic brake control module). Now when one part of this assembly fails, you need to replace all of it. Some of these brake control module and valve assemblies can cost $1000 just for parts.

In another example Chevrolet cars and trucks experimented with one of these combination brake computers and valve assemblies for several years. These units manufactured by Kelsey Hayes failed in large numbers. Aftermarket companies jumped in to take advantage of this business opportunity. They rebuild or repair your original component and send it back to you. Therefore, a little research on your individual problem might uncover cost-effective solutions.

Anti-lock Brake System Normal Operation

After you buy a new used car you could wind up operating it for years without using the ABS system. In other words, drivers can go for long periods of time without needing to use a panic stop function. Then when an emergency occurs, these drivers can hear and feel harsh engagement of the antilock safety feature for the first time.

It’s common for drivers to think there’s a problem with the brake system. Mechanics highly recommend that car owners become familiar with how this safety feature performs when everything is working correctly. In fact, dealers that sell you an ABS equipped vehicle should demonstrate how it operates. Unfortunately, this rarely happens.

So it might be up to you to learn how the system feels. Get use to judging the total stopping distance from different speeds and road surface conditions. Taking the time to do this remains a better solution than being surprised by the first panic stop in an emergency situation. This prevents drivers from complaining about common ABS system problems that actually indicate normal operation. Things like the violent push-back from the brake pedal, a buzzing or grinding noise when the system becomes active indicates proper function on many models.

The ABS System Ties into Other Safety Features

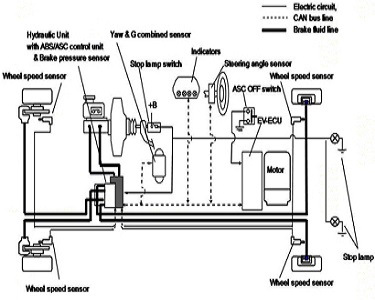

Car manufacturers use ABS system components to operate other safety features. A prime example of this is the traction control system. When a wheel speed sensor detects a wheel or tire slipping, the brake control module gently applies the caliper, restoring traction to that tire. Stability control systems also use the vehicle speed sensor, wheel speed sensors and the anti-lock brake system to help keep the automobile straight on the road.

Therefore, when experiencing common ABS system problems additional dash warning lights often illuminate. A malfunctioning wheel speed sensor is an excellent example of this. If the computer sees a missing wheel speed input signal, it turns on the warning light for all systems that use the information from the sensor.