Did you know that in 2022, the U.S. steel market reached 97.5 million metric tons?

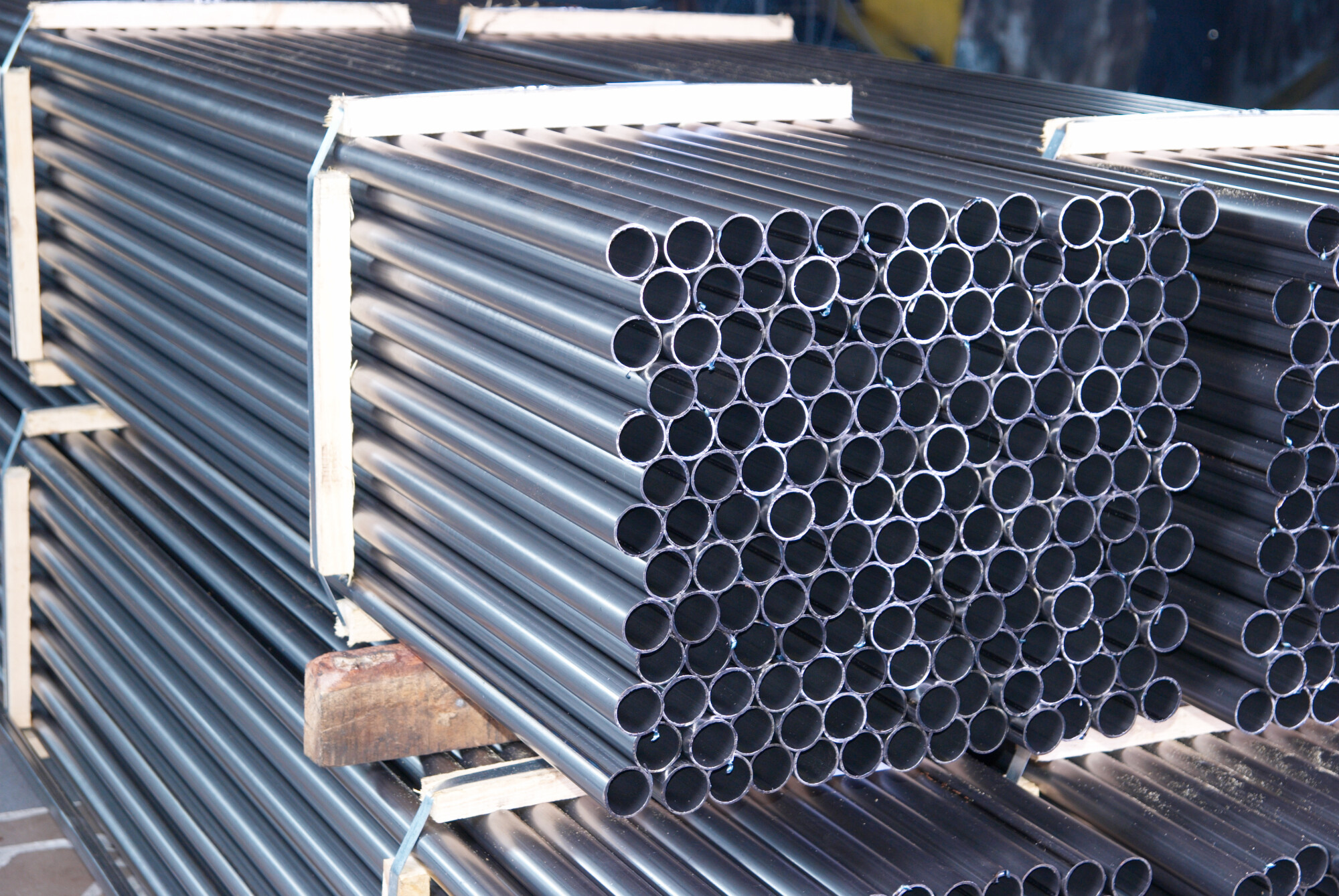

Steel is one of the most common building supplies used to create industrial facilities. It can be used in large or small quantities, depending on your needs.

Because of this, steel supplier is far and wide. You can find them online or through local ads, but how do you choose the right one?

Because steel suppliers come in a wide variety of shapes and sizes, it might seem like buying steel through one of them is a daunting task. Read on to learn more.

Evaluating Capabilities

Look at their product offerings and make sure they will be able to fulfill your needs. An experienced supplier should be able to offer high-quality steel and meet any technical requirements. They also should be able to demonstrate an understanding of industry standards and be able to provide samples.

In addition, you should inquire about their processing capabilities; can they cut, shape, form, and finish the pieces you require? It is also vital to know their industry experience and success rate of delivering on time and within a budget.

Finally, ask for references and reviews from current and past customers. Doing research ahead of time will ensure you choose the most suitable steel supplier for your project.

Steel Types and Grades

Different steel types and grades are needed for other applications. Generally, the higher the steel grade, the more suitable it is for rigorous applications. Finding a supplier willing to meet some applications’ unique requirements is also essential.

Researching the different grades and types of steel the supplier offers is essential. Suppliers should also be asked if they can provide hardness testing or any other certifications the steel may need.

Finally, the supplier should be able to explain the steel grades and types in detail and answer any questions you may have. You can ensure you get the best quality steel from the most reliable supplier.

If you are looking for some structural-steel angles available and the highest-quality structural materials, visit Bushwick Metals.

Quality Assurance

Look for suppliers who have a reputation for consistent quality. Speak with each reference and ask comprehensive questions about the quality of the products they received.

Visit the steel supplier’s warehouse and ensure the environment is clean and organized. Speak with the production supervisor and ask if they have implemented quality assurance measures or standards.

Weighing Delivery Options

When buying steel, consider the delivery timescale. Does the supplier offer next-day delivery or longer?

Also, look into flat-rate delivery costs and discounts. Many suppliers will offer such discounts if customers meet a certain spending threshold.

Additionally, you might need to examine local city ordinances to assess viable delivery options. Some cities might restrict the size of trucks serving different areas. Be sure to consider any potential hazards when shipping steel too.

Some steel mixtures, such as carbon and various alloys, are classified as hazardous materials and require special shipping arrangements. Once you’ve weighed all the delivery options, you’ll have an easier time choosing the best steel distributor.

Choose the Best Steel Supplier

Choosing the right steel supplier for your project can be a difficult decision. Remember to weigh supplier choices based on price, product quality, and customer service. Doing your due diligence in researching and finding a reputable steel supplier will enable a successful experience for you and your project.

If you enjoy this article, check out our blog for more exciting content!