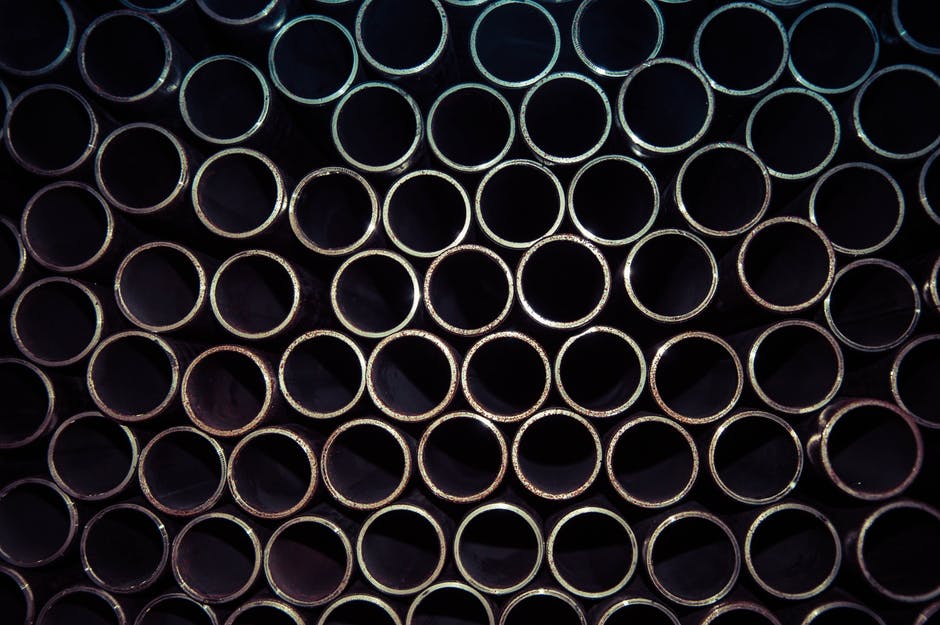

In a wide variety of industries, ranging from chemicals to construction to heavy manufacturing, stainless steel tubing is one of the most versatile and commonly used metal alloy materials. When choosing the right kind of tubing for your business, you will have to make some important decisions.

One of these is concerns welded vs seamless stainless-steel tubing. Seamless tubing is the more popular form of tubing for a wide variety of reasons.

To find out whether it is the right one for you, here are four essential things you need to know about custom seamless tubing for your business.

1. Seamless Tubing Is Manufactured Differently

First off, it is first worth noting how seamless tubing is manufactured. As you probably know, welded tubing is made by simply ‘welding’ different lengths of steel piping together.

Seamless tubing, meanwhile, is truly seamless. It is created using a process called ‘extrusion’ in which a steel bar pierces through its center using a die, creating an ultra-solid and lengthy tube.

There is cold drawn seamless tubing, made from SAE 1018 steel, which has a smooth finish. Then there is hot finished seamless tubing, made from SAE 1026 and with a scaly finish.

2. Seamless Tubing Is Stronger

Put simply, seamless tubing is stronger than other types of tubing. This is especially true of more premium types such as seamless nickel alloy tubing. By definition, seamless steel tubes are completely homogenous, without any of the vulnerabilities that welded tubing has.

This means that it is stronger, has much better resistance to corrosion, and is able to withstand higher levels of pressure than other types of tubing. This is what makes seamless tubing so popular in a variety of heavy-duty industry. For durability and strength, the answer to the seamless vs welded tubing question is obvious.

3. Seamless Tubing Is Popular in Certain Industries

Of course, seamless tubing is not the most ideal tubing for every type of application. However, its unique properties make it most popular within a select group of industries and applications.

Its most common use is probably within the energy industry, where its durability and length make it ideal for oil and gas control lines. For these same reasons, they are also a popular choice for chemical injection valves, as well as any application that requires undersea safety valves.

It is especially popular as a form of pressure tubing, which is sold by tubing specialists such as this company here. Its resistance to corrosion also makes seamless steel ideal for steam and heat transfer in chemical processing plants.

4. Seamless Tubing Is Cost-Effective

Finally, it is important to remember that seamless tubing can often be more cost-effective than other forms of tubing. Granted, many types of seamless tubing have a higher upfront cost than welded tubing.

However, this is not the full story. Seamless tubing lasts longer and requires less maintenance.

It can also be cheaper when buying in very large quantities. This means that the medium and long-term cost savings of seamless tubing over other types of tubing can be significant.

Essential Maintenance Tips

Seamless tubing is popular for a wide variety of applications and industries. If you’re looking for tubing that is durable and able to handle immense amounts of heat and pressure, then seamless tubing is right for you.

Whether it’s seamless tubing or the car engine that is giving you maintenance trouble, we are here to help. For all of the latest expert maintenance tips on the things that matter, make sure to consult our extensive and expertly curated Maintenance guides today.