When people have car problems requiring replacement of specific parts they often think they only have two choices. Buy a rebuilt part or purchase a brand-new one.

However, a third option exists for those with a do-it-yourself mindset. You can rebuild almost any part available in a remanufactured version. Yes, the car owner instead of a shop. Therefore, we’ll review the top three automotive parts you can rebuild yourself instead of replacing.

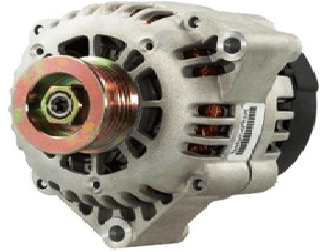

Rebuilding Automotive Alternators Depending on the Year

When an alternator fails the root cause of the problem is usually an internal electrical failure. In some cases an alternator will make noise which actually indicates the failure of one of the two bearings. A brand-new replacement alternator can be extremely pricey on some models. A overhauled unit is less expensive, but often less reliable.

I don’t know how many times I pulled a rebuilt alternator out of the box, went through the hassle of installing it and it didn’t work. Sure, the auto parts store replaced it, but they don’t reimburse you for the labor it takes to remove and replace the alternator two or three times. The alternative to a new or re-manufactured part is to rebuild the alternator yourself.

The caveat to this is an overhaul kit isn’t available for all makes and models. Personally, I search down the overhaul kit before I make the decision on whether I’m going to rebuild the part or buy a new one. If the kit is available, I look at what’s included and then I make my decision from there. Most alternator overhaul kits are in the $50 and under price range. In fact, on older automobiles these kits might be under $25.

The kit includes both bearings, a new set of electrical brushes, a diode trio, the rectifier bridge and on some units they also include a voltage regulator. We don’t have to get into diagnosing each individual component, because we might as well replace them all once we take the screws out of the case and open the alternator up. The high quality kits include complete instructions and most of the time you don’t need any special tools.

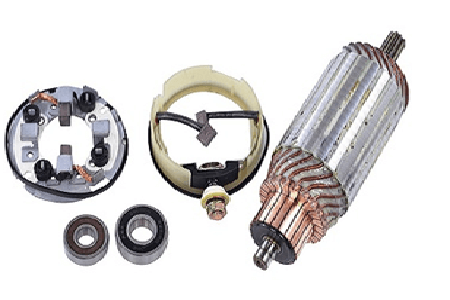

Rebuilding an Automotive Starter Motor

An automotive starter motor problem is another issue you can solve by buying a new or re manufactured component. Unfortunately, just like my experience with rebuilt alternators, you don’t always get a good replacement starter right out of the box.

The interesting thing, after you have overhauled a few starters, you’ll find the main failure in many of these units is the electrical carbon brushes. This especially true on German cars like the Mercedes Benz C Class or the BMW 5 Series automobiles. Diving a little deeper into the issue, you find these worn out brushes installed on high mileage automobiles. A complete overhaul kit for a starter can cost as much as a new part on some year, makes and models.

This is mainly because the overhaul kits include a new armature. They also include new front and rear bearings. Since the starter motor doesn’t spin all the time like the alternator the bearings aren’t usually the problem. The Armature is a heavy long-lasting component and can often be cleaned or reconditioned. If you only need new carbon brushes, you’ll find new sets for popular models under the $20 mark. This applies to both foreign and domestic automobiles.

When I decide to replace the brushes, instead of replacing it with a new starter, I disassemble the case and make sure there’s no internal damage. Another thing I inspect is the commutator bars on the armature. When the brushes wear out the carbon works into the spaces between the commutator bars. You want to make sure you can clean this out and there’s no damage to the surface, because this is where the new brushes will ride.

If I disassemble the starter and I find the armature needs replacing, I put it back together and take it to the parts store to trade it in against a new or rebuilt starter motor. As in the case with the alternator a core charge is also due for a starter motor. The automotive parts company will return it to their factory where it’s reconditioned and then resold to the next customer.

Rebuilding a Front Wheel Drive Axle Shaft

If you own a front wheel drive car long enough, it will experience a CV joint problem. The CV stands for constant velocity. Basically this is a large heavy duty universal joint that drives the wheels while they’re turned and go up and down. The factory covers the CV joint on a front wheel drive car with a flexible rubber boot. After a couple of decades, this rubber begins to harden and develop cracks.

When this happens the grease that lubricates the joint begins to escape through the compromised boot. As the lubrication level decreases wear increases on the CV joint. Drivers of high mileage front wheel drive cars will often complain about a clicking or grinding sound from the wheel area when this situation occurs. The complaint is most evident when the car is taking off from a stop with the wheels turned.

Most auto repair shops will go ahead and replace the entire length of driveshaft. This includes the inner tripod joint that attaches to the transmission, the shaft, the outboard CV joint and the hub assembly. It seems kind of wasteful to replace this entire unit when the only bad part is the CV joint itself. However, with stiff competition, rebuilt driveshafts are often available for popular models at very reasonable prices.

Therefore, before you decide to replace the CV joint perform some due diligence and shop prices on a overhauled unit. Using a specific example of a Dodge Avenger with a 2.0 L 4-cylinder or 2.5 L V6, a new CV joint kit comes with a price tag around $75. A rebuilt driveshaft, complete and ready to go comes in around $200. Since there’s a bit of work involved in replacing just the CV joint you’ll have to make this judgment call on your own.

What special tools will I need? A basic set of snap ring pliers is usually the only odd tool that you might need. It’s also recommended that you check your Dodge auto repair manual for the procedure for your specific model. If you’re comfortable with what’s involved in just replacing the CV joint you’ll save about $125 on the repair.

Automotive Parts you can Rebuild on Old Cars

If you own an older car that’s not fuel injected there’s one automotive part your car has you should consider rebuilding. When these old rides start running poor, getting rotten gas mileage or stall it might be time to rebuild the carburetor. Reconditioning this low tech fuel delivery system makes a great weekend project. See if you should replace or rebuild an old carburetor.